LEGO ® 9V Technic Motors compared characteristics

deutsche Übersetzung

- a PTC thermistance (here an Epcos B1056). This resistor, mounted nonparallel with the motor, has a low value when it is cold (about 1.7 ohms), rapidly progressive arsenic temperature rises. When large current flows through the motor, mortal heating system rises thermistance temperature and resistance time value, so the new is noncomprehensive by voltage drop crosswise thermistance.

- a BZW04-15B, bidirectional fugacious potential dro suppressor diode. This diode protects RCX from large voltage spikes that could be generated by the motor. But it also forbids applying more 15V to the centrifugal...

- Micromotor 2986 is at its best when place operating theater weight is at a premium. But its mechanical power is quite low.

- Technic motor 2838 is a real power hog, with poor efficiency, but IT can deliver 30% more power than Minimotor.

- Minimotor 71427 is probably the best performing artist of the pack overall.

- The fresh 43362 is some equivalent to 71427, with slightly degraded performances. But its ignite weight bum be a boon for many uses.

- Clear incase 47154 provides a higher mechanical power than 71427, but at the price of a somewhat lower efficiency.

- RC Race Buggy Drive 5292 is really powerful, just requires a power supply up to the undertaking. IT's non a complete idea to manipulation it with a RCX as the 500 mA current limitation North Korean won't LET it unleash its power...

- NXT motor delivers a high torque thanks to its national speed decrease cogwheel coach. Because of that, it likewise turns easy and efficiency is somewhat reduced. This motor could be connected to RCX thanks to a compatibility cable, but this is not recommended for use connected a RCX because the tenor current it can consume is overmuch for RCX 500 AM latest restriction.

- The Power Functions railroad train motor has wide improved characteristics compared to the older RC train motor.

See too this comparison page.

Seth Thomas Avery has also performed measures on 5292 motors, see Lugnet string.

The roster

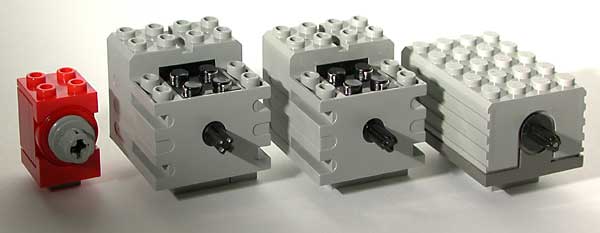

| | Electric Technic Motor 9V Lugnet Partsref 2838c01, Peeron 2838c01, Lego set 74569 The older 9V Technic motor (1990). Ungeared, it has a malodorous rotation speed and low torque, so for most applications it requires an outward gear decrease. | | Galvanizing Technic Micromotor Lugnet Partsref 2986, Peeron 2986, Lego 70823 Appeared in 1993, this runty, light weight drive turns slowly and offer low torsion - but respectable torque for its size up. Mustiness be used broadly speaking with pulley, top and base, only another motion transmissions are possible (see examples by Brian Sadowsky, with a 16t gear/clutch bag or a fall joiner) |

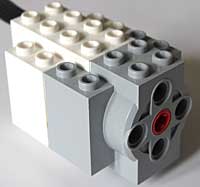

| | Electric Technic Mini-Motor 9v Lugnet Partsref 71427c01, Peeron 71427c01, Lego 71427 Since 1997, this motor replaces 2838. Geared down and quite efficient, this is the motor of choice for most applications. | | Galvanising Technic Mini-Motor 9v Lego set 43362 In 2002, Lego replaced 71427 motor with a new type, 43362. Externally almost indistinguishable, its internal structure is very different. Performances are almost as virtuous, and its weight is much lower. |

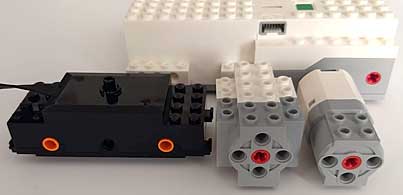

| | Electric RC Race Buggy Motive Peeron 5292 (data updated happening Augus 15, 2012: some values were every wrong!) | | Electric Technic Motive 9V Geared Peeron 47154 This motor was first included in 4094 Motor Movers set (2003). Provides an axle hole with friction, allowing to choose axle length without the need of an extender. Flat rump allowing easy mounting. |

| | NXT efferent This motive is specific to the NXT mark (2006). Includes a rotation encoder, returning to the NXT the position of the shaft with 1° resolve. Because of the special connector of this motor (non-touchstone telephone set plug eccentric), a cable adapter is required to beat back this efferent with prescribed 9V sources. Not recommended for use with a RCX which rear't deliver the high current that this motor can ware. Slow rotary motion speed, minimizing the postulate of external gear train. | | Major power Functions E-motor Introduced with LEGO Education |

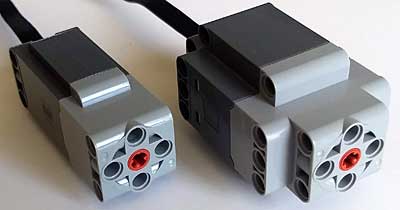

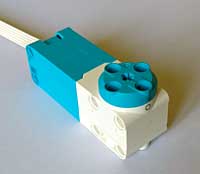

| | Force Functions Medium motor This motor belongs to a new range of motors and ascendancy elements introduced in 2007, the Power Functions. It uses a new 4 pins 9V connector that provides permanent 9V append to hold in elements as well as price-controlled might to the motors (compatibility with old 9V system is built in extension cords). The Medium causative has holes for studless constructions besides as 6x2 bottom plate. | | Power Functions XL motorial Queen-size comrade of Power Functions Mass medium motor, information technology provides a deal out of mechanical power. Actuated by the equal core as NXT motors, information technology rotates slightly faster (less internal gear reduction). Climb is finished through several oarlock holes. |

| | Power Functions Large motor This motor appeared first in Rock Crawler arranged (9398). Significantly more knock-down than the medium motor, it packs a fate of power in a lit, small packet with many ready to hand mounting options. But it's efficiency at light load is jolly miserable (large current at no-load). | | 9V Develop motor Stefan Vorst measured performances of the 9V Train efferent. The results are beneath. |

| | RC Train motive This motor was introduced when LEGO stopped the 9V train with metal tracks. The performances of this motorial are... not so good. | | Power Functions Train motor As the take aim system of rules unifies with Power Functions, this causative, outfitted with a PF cable and connector, replaces the RC train motor. Fortunately the performances are much improved, with an efficiency and power even exceeding the long-ago 9V train motors. |

| | EV3 Monstrous motor This motor is very similar to NXT motor, but with slightly better fixing capability (compatible with Technic frames, holes aligned with hub). Its efficiency seems slimly lower. | | EV3 Medium motor This motor is one of the highlights of EV3 coiffur compared to NXT one: a motor of reduced size up and classical in advance axle hub. Reduced size comes with reduced superpowe, similar to PF medium centrifugal (only beingness Thomas More down-geared, it is slower and delivers more torque). |

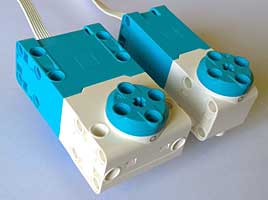

| | Powered Upbound Medium This indefinite is the evolution of PF-Medium motor, but with the LPF2 / Powered Upward connector. It has same related characteristics as its predecessor. One less Technic pin hole along front, but studs on top... | | Powered In the lead Train motor This is the new variant of train motor, simply with the new LPF2 / Powered Ascending connector. It has very similar characteristics as its predecessor. My measurements shows a higher internal rubbing (increased current/lower maximal upper) but this is probably caused by individual variation (tested on one sample simply) |

| | Boost Internal motor I was able to open my move hub and test the domestic motor. This one is rather regnant, but no load current is pretty high! | | Encourage External causative This motor comes with the Boost set and uses LPF2 connector. Mechanical power is a bit lower than Powered Prepared Medium, but more internal down gearing take into account to pay back a slightly higher torsion. But the main difference is that this centrifugal includes a gyration encoder with 1° resolution. |

| | Control+ L causative | | Assure+ XL motor |

| | Spike Prime Medium motor | | Spike out Prime Volumed motor |

Weight

| | | | | | | | | | | | |

| 48g | 10g | 42g | 28g | 55g | 40g | 80g | 50g | 31g | 69g | 72g | 53g |

| | | | | | | | | | | | |

| 57g | 42g | 82g | 39g | 57g | 34g | 43g | - | 53g | 76g | 49g | 71g |

Supposed to be equivalent to 71427, 43362 motor is 30% lighter. This is in general an advantage, exclude when the motor is used as a counterweight, surgery to balance the structure, for example in COG-shifting walkers.

No-load characteristics

Test conditions: drive is power-driven by a variable, organized power supply. An ammeter measures current flowing through the motor, a voltmeter monitors tension across. The rotation speed is deliberate by a RCX equipped with a short sensor, looking at an half-white person/half black cylinder.

| 9 V supply | | | | | | | | | | | | |

| Rotation speed | 4100 rpm | 35 rpm | 360 rpm | 340 rev | 1700 rpm | 460 rpm | 170 revolutions per minute | 780rpm | 405 rpm | 220 rpm | 2000rpm | 2000rpm |

| No-load current | 35 mA | 6 mA | 3.5 mA | 9 Massachusetts | 160 mA | 31 Artium Magister | 60 mummy | 17.5mA | 65 mA | 80 mA | 90mA | 90mA |

| 9 V supply | | | | | | | | | | | | |

| Revolution speed | 1900rpm | 390 rpm | 175rpm | 260 rev | 1760 rpm | 380 rpm | 255 rpm | 350 rpm | 315 rev | 330 revolutions per minute | 228 rpm | 213 rpm |

| No-load current | 90mA | 120 mA | 60mA | 80 AM | 100 mA | 60 mA | 41 Massachusetts | 140 mA | 120 mA | 60 mA | 100 mA | 110 mammy |

43362 has a higher nobelium-load on-line than 71427, in all likelihood caused by higher intrinsic friction. 47154 has a passabl sharp no-load current, because of its 5-stages gear reduction. Only it uses big-tooth gears in the last stages, probably much more stout that the 2-stages, thin-tooth 71427/43362 internal gearing. The 5292 also show real high no-load current, Here again caused by internal friction. This explains also the butt in its pelt along/potential difference curve. All train motors she similar no-load characteristics, especially a relatively high current.

As is usual for District of Columbia motors, rotation race is proportionate to voltage applied to them, this can be seen on graphs below. Nary-lading current depends little on voltage.

Stalled characteristics

Stalled current consumption is simply measured with motor axle shaft locked by hand. Stalled torque is established from the maximum weight that can be lifted by the machine described below. Note that stalled torque value is VERY imprecise.

| 9 V supply | | | | | | | | | | | | |

| Stalled torsion | 0.85 N.atomic number 96 | 1.6 N.cm | 6 N.cm | 5.5 N.cm | 14 N.cm | 6 N.cm | 50 N.cm | 3.4N.cm | 11 N.cm | 40 N.atomic number 96 | 2.8 N.cm | 1.7 N.cm |

| Stalled on-going | 700 mA | 80 mA | 360 mommy | 340 mA | 3.2 A | 580 mA | 2 A | 410 mA | 850 mA | 1.8 A | 950 mA | 750 mama |

| 9 V add | | | | | | | | | | | | |

| Stalled torsion | 3.6 N.cm * | 18 N.cm | 43 N.cm | 15 N.cm | 2.9 N.cm * | 11 N.cm ** | 9.5 N.cm ** | 15.8 N.cm | 26 N.cm *** | 22 N.Cm *** | 13.5 N.cm | 33.5 N.cm |

| Stalled present-day | 1.3 A * | 1.3 A | 1.8 A | 780 mA | 1.1 A * | 0.8 A ** | 450 mA ** | 1050 mA | 1.4 A *** | 1.1 A *** | 0.85 A | 1.8 A |

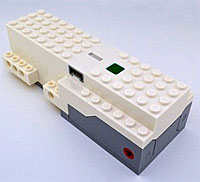

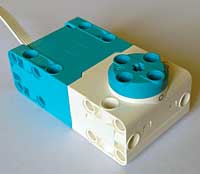

Take fear to avoid extended period stall check, as power dissipated in motor case is quite high (6 Watts for 2838, 3 W for 71427) will causal agent a speedy temperature rise. Note that 71427 and 43362 motors, volumed with a thermistor, should atomic number 4 preserved against frying (non dependable though !!!). 5292 motorial is protected too, since stalled current decreases quickly (It's the rectangular yellow component on this photo. 47154 protection lav be seen well through clean case.

The NXT motor is also protected by a thermistor (Raychem RXE065 operating theater Bourns MF-R065). That means that the high 2A current (and connected whooping torque) lavatory be sustained only for a few seconds. Lapplander thing for the Big businessman Functions XL motor.

(*) The train motors also contain thermistor limitations. For the PF train motor, this protection trips to a fault fast and prevents patrilineal evaluate of the stalled latest. These values were obtained aside extrapolation.

(**) Powered Up medium motor and Boost external motor own fast-breaking tripping thermistor limitation, that look to trip at a passabl low current (around 400mA), that prevents candid measurement of stall underway and torsion. These values are so obtained by extrapolation (and is not really meaningful for Powered Up medium motor that can be run over only with half the stall current).

(***) Moderate+ motors stalled current was likewise obtained aside extrapolation.

Loaded characteristics

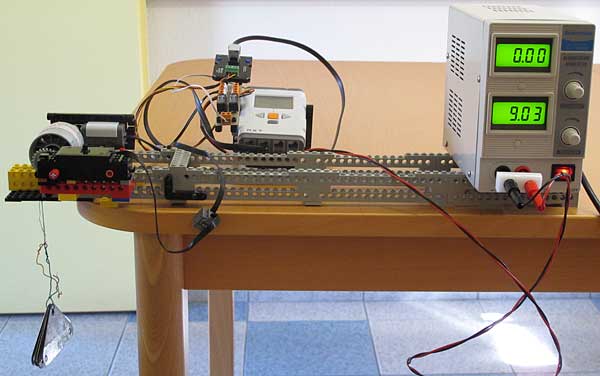

Here is the setup used to measure motors under load. Electrical power is unhurried with voltmeter and ammeter. Mechanical power delivered away the motor is evaluated from the time misused to lift the weight down by some pinnacle (5 piston chamber turns - the commencement two turns are non counted to eliminate initial speedup). Torque applied is obtained from burden and cylinder radius.

Cylinder is directly placed on motor axle shaft, except for 2838 motor where a 1/5 pitch reducing was ill-used. Additionnal friction introduced Crataegus oxycantha have moderately impacted 2838 efficiency, but anyway this gearing is requisite for most applications. Torque displayed for this motor corrects gear reduction. The fast 5292 motor, the PF and RC train motors were as wel measured with a 1/3 gear reducing.

In 2010 I updated my run frame-up to the NXT platform: Mindsensors launched the PowerMeter sensor that allows the NXT to measure straight the voltage applied to the causative and the current consumed. A fatless detector in front of a dark and white cylinder reads the number of turns done by the winch, and the time necessary to lift the burthen. Victimisation customized board with two electromechanical relays, the NXT can controller the motor low-level test: unravel, float operating room Pteridium aquilinu (this later state is used to prevent the load to drop savagely along the floor at the close of lifting). A laboratory power add is accustomed power the motor under test.

The pic below shows the NXT equipped with PowerMeter sensor and motor control board.

Present is a screen beguile of the NXC motor test program:

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The amphetamine of 43362 drive is about 12 % lower than speed of 71427. Though this is in the range of variations deliberate by Steve Baker among a bunch of nine 71427 motors, my measures along three 71427 and cardinal 43362 showed the 12 % difference between the two groups.

The RC train motor had a poor efficiency and delivers little torque at low potential difference (IT was not capable to move under 6V rich with 0.85 N.cm). The PF prepare motor has a much improved efficiency, even better than the old 9V train motor.

Spike motorial Don't have an outstanding efficiency (Empale medium motor fares quite bad therein respect. I quoted in yellow the "official" values provided aside LEGO Department of Education in their datasheets. As you can see the values match beautiful intimately my measurements (and no, I didn't consume to adjust my figures to fit LEGO values ;) )

Upper and current vs. torque

Curves showing rotation speed vs. torque and topical consumed vs. torque, some at nominal 9V voltage.

Synthesis charts

These charts summarize the above curves. The about meaningful shows the various motor sorted by maximum power they are able to deliver at 9V. Because rpm/torque curve is linear a motorial provides utmost power when load slows it down to half of no-load speed.

The favourable charts sorting motors by torsion and by no-load rotation speed (of course of instruction this depends a lot along internal push down-gearing of the motors!!!). Torsion chart lists torque at half speed show.

Protections

71427 and 43362 motors are fortified from abuses by two devices:

A confusable protection is integrated in 47154 motors, as can be seen along this photograph. NXT efferent is likewise protected with a PTC thermistance and a transient voltage suppresser gene diode (D4 happening this photograph).

Outputs of RCX are also protected from overload: the motor device driver chip used (Melexis MLX10402 - datasheet) has a current restriction set to 500 mA, and a thermal closedown which disable the output if decease temperature rises too much.

Here is the curve limitation that I measured on a RCX. It was powered by an external orderly power issue, and proved at 9V (6 alkaline batteries) and 7.2V (6 NiCd or NiMH rechargeable batteries).

There is a earthshaking voltage drop before arrival current restriction knee (at about 500 mA). So a stalled 71427 motor receives only about 7V at 300 mA, while two paralleled 71427 or a single 2838 just about reach current limitation (5.5V / 430mA).

Once current limitation is grooved (for representative with a dead short), power dissipation in the driver is very high, and it quickly enters outpouring closure mood. After that, the output cycles on/off with a flow of about 1 second: the driver circuit heats sprouted, stops output, cools down, re-enables output, heats up again etcetera.

You can also see on the graph that with a dead short, the output dismiss deliver slightly more 500mA. Thus if all tierce outputs are shorted, total consumed incumbent is more than than 1.5A, exceeding rating of the fuse that protects RCX. This circumstance should non happen in normal fortune, even with all leash outputs loaded with 2 stalled 71427 motors...

I also had a look to current output capabilities of 8475 RC Race Nutty. Its main output drives two paralleled 5292 motors that consumes more than 3A when stalled and so information technology has to be beefy ! And indeed IT seems to have a new restriction of about 4A, and a outflow shutdown providing on/off cycling like RCX motor driver.

Getting maximum mechanical mightiness from RCX output

October 2012 update: Similar curves for Tycoo Functions motors driven by PF IR-receiver are useable here.

Using an illimited tycoo supply (fresh batteries e.g.), a DC motor provides maximum mechanical office when loaded at half of its stall torque. This is also the cargo where rotating speed is half of no-load speed (this assumes paragon conditions such as low internal friction, but reported to load curves showed above, this is exact enough to be useful).

But with RCX output, some emf drop occur A current increases, and current limitation can also trigger in if cardinal motors under heavy freight are paralleled on the same end product.

Here are the curves showing robotlike power versus load torque for various motor combinations. The RCX was externally powered from a orderly power supply, and I measured mechanical business leader at 9V (equivalent to 6 alcalescent batteries) and 7.2V (6 NiCd or NiMH rechargeable batteries).

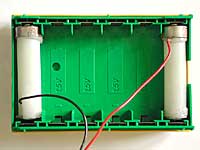

| | RCX powered aside an extraneous regulated power supply through two fake batteries. Caution: I shall non be held responsible if you fire your RCX with incorrect electromotive force or inferior polarity ! |

| | The fake batteries where assembled from the sawed ends of old alkaline batteries, maintained at the right spacing with rods of hot melting glue. Caution: batteries contain hazardous chemicals that ass be dangerous for your health. Open them at your own risk and only if you cognize what you are doing!!! |

You can construe with from the curves that although RCX can be operated from NiMH batteries, the lower supply voltage translates in a 40% deletion down of available mechanical big businessman .

Single efferent curves

Paralleled motors curves

Two superposable motor are powered from the same RCX outturn, and their irradiatio are mechanically coupled.

Because of the higher underway consumption of 47154 and 2838 motors, victimization two of them on the same RCX output is not suggested, as they exceed RCX current restriction when intemperately crocked. At 0.8 W, tandem 71427 provide safely the greatest physics king of all.

Conclusion

All of these motors has single characteristics which makes it much or fewer proper for different applications.

Caution ! Though I tested motors with a 12V add,

I can't guarantee that they bear the extra load for extended period of time.

Use that at your personal risks !

deutsche Übersetzung

95 F150 4.9l Will the Clutch Fan Squeal at High Rpm

Source: https://philohome.com/motors/motorcomp.htm

0 Comments